Broach blade only - tang hole saw for fitting stick tang blades

Broach blade only - tang hole saw for fitting stick tang blades

Couldn't load pickup availability

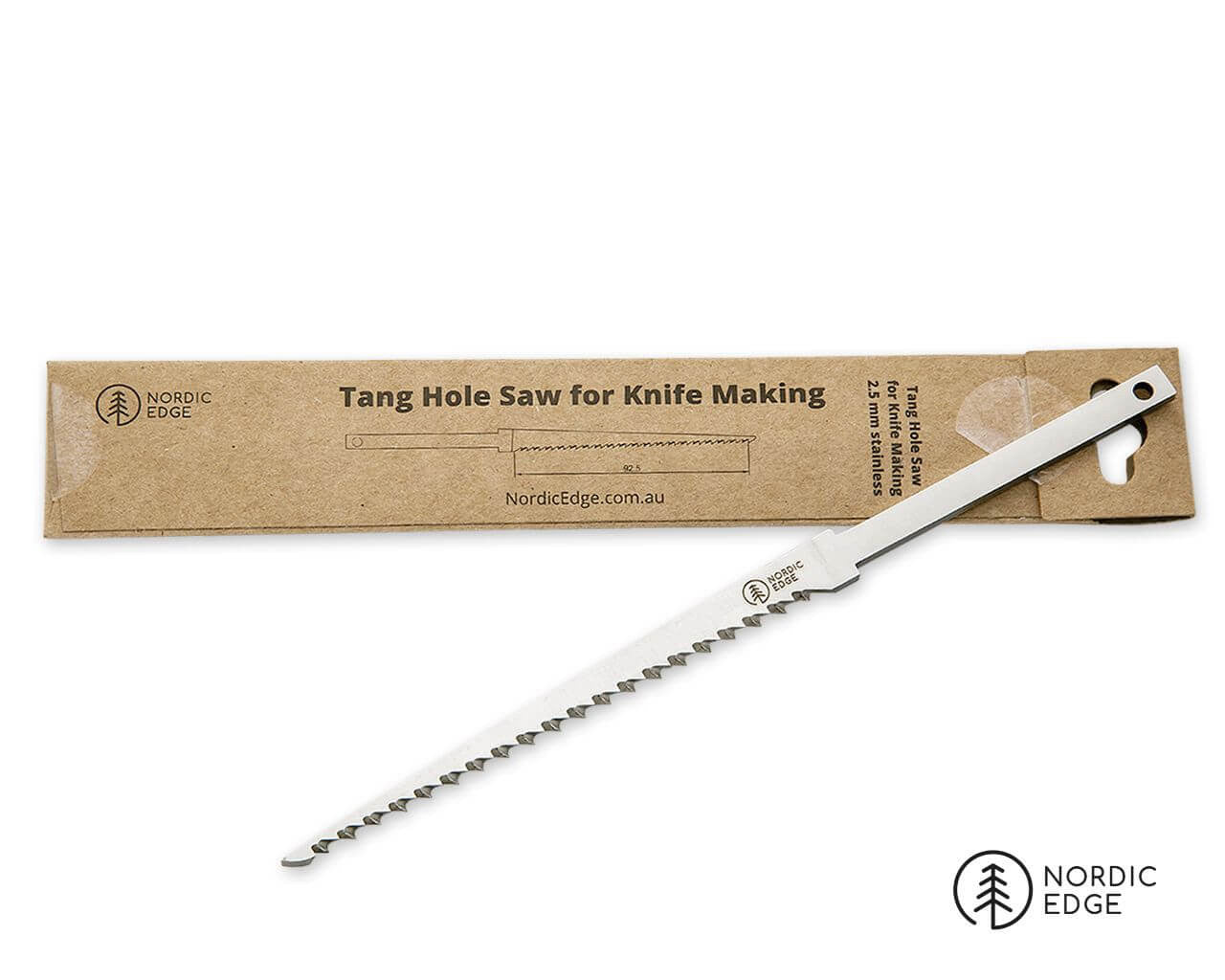

Broach - Tang Hole Saw Blade for Knife Making

This tool from Nordic Edge is our version of the tang hole saw, or "broach".

A broach is used when fitting a stick tang blade into a handle block,

by rasping drilled holes into a slit or hole that matches the tang of the blade.

This is the broach blade only for those wanting to make their own custom handle.

The blade is made from stainless steel 5Cr15Mov, a tough and highly corrosion-resistant steel tempered to 56-57 HRC.

The blade is 162.8 mm long (6.4") including the tang, and about 2.6 mm (0.1") thick at the teeth.

The sharp section of the blade is about 96 mm x 2.6 mm (3.77 x 0.1") with the Nordic Edge logo lasered on.

How to use the broach:

- accurately measure the tang of the blade where the handle will start

- scribe this onto the handle block

- drill a series of holes smaller than the marked area in a straight line

- use the broach to remove the handle material between the holes to create a slit

- rasp out the rest of the marked area, stopping often to test fit the blade

Why not practice by making a handle for the broach blade itself?

Broaches are not a new thing, most of us have some version of this already in our arsenal. Some use a short jigsaw blade fitted in a block of wood, others use a set of small files or wood rasps. This is just our take on the tool, with a blade narrow enough to get into holes 3 mm in diameter for fitting most blades except really thin chef blades, with agressive teeth for fast stock removal in wood and synthetic handle materials.

The Nordic Edge broach is designed by Nordic Edge in Australia and manufactured in China.

There is also a version with handle already made in maple wood, should you prefer to get it ready to use out of the box: LINK

Pro tip: When fitting a stick tang blade, using a carbide faced file guide to cut shoulders in the blade before fitting it makes for an even cleaner looking blade/handle fit. As the blade then has a shoulder to sit on, the tang hole can be made slightly narrower than the blade.

Share